In the rapidly growing and ever-evolving world of plastic processing, granulators have become indispensable machines for ensuring efficient material handling and recycling. A medium duty granulator strikes a perfect balance between performance and cost, making it one of the most commonly used machines in various industries. These machines are designed to process plastics such as sprues, runners, and rejected molded parts, breaking them down into usable granules that can be reintroduced into the production process. With the demand for high-quality granulators growing exponentially, the need to choose the right medium duty granulator manufacturer becomes crucial for businesses aiming to optimize their production and reduce waste.

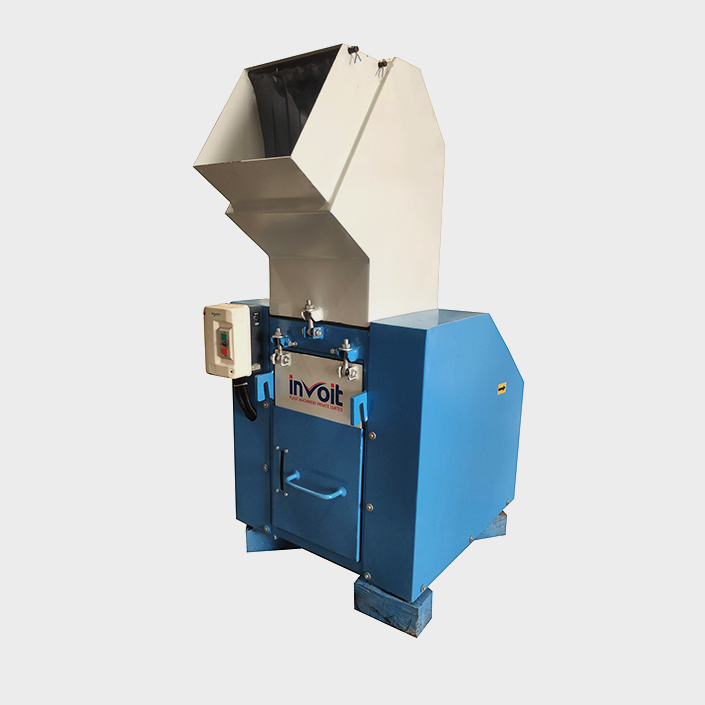

India’s manufacturing sector, particularly in the plastic processing industry, has witnessed significant growth, driven by technological advancements and increasing global demand. In this highly competitive market, it is essential to partner with a manufacturer who can offer top-tier medium duty granulators that guarantee performance, reliability, and cost-efficiency. This blog will delve into the key features that set the best medium duty granulator manufacturers apart and explain why Invoit Plast, a premier medium duty granulator manufacturer based in Ahmedabad, India, should be your top choice.

The Importance of Quality in Medium Duty Granulators

When it comes to selecting a granulator, one of the foremost considerations is the quality of the machine. The best medium duty granulator manufacturers focus extensively on product quality, as even a slight design flaw can lead to significant operational disruptions. A high-quality medium duty granulator is built to withstand the rigors of continuous operation without compromising performance.

Leading manufacturers prioritize precision engineering and the use of durable materials to ensure their machines are long-lasting. For example, the rotors, cutting blades, and screens of these machines are crafted from hardened steel, ensuring they can withstand the wear and tear of processing tough materials. Furthermore, quality granulators are designed with advanced rotor configurations that ensure efficient cutting, resulting in consistent granules and reduced power consumption.

When choosing a manufacturer, always look for companies that are committed to adhering to strict quality control measures and use ISO-certified production processes. This guarantees that each machine meets global standards and is reliable enough to handle the demands of various industries.

Customization for Specific Applications

Plastic processing involves a wide range of materials and applications, and not all materials can be processed using the same type of granulator. The best medium duty granulator manufacturers offer a wide array of customization options to tailor the machine’s specifications according to the unique needs of their clients. This customization can include adjustments to the rotor design, blade configuration, screen size, and even feeding systems.

For example, industries like injection molding and extrusion may require granulators that can handle large batches of material, while others may need more precision for smaller particles or specialized applications. With a customized granulator, businesses can ensure that the granulation process is optimized for the specific materials they are processing, whether that’s ABS, PET, PVC, or polypropylene. Moreover, some operations may need additional features, such as noise reduction or energy-efficient motors, to ensure smooth operation and reduced operational costs.

Leading manufacturers like Invoit Plast specialize in providing tailored granulation solutions that are designed for superior throughput, minimal downtime, and long-term durability. This ability to customize the machine according to application requirements ensures maximum efficiency in production.

Incorporating Advanced Technology and Automation

In today’s competitive manufacturing environment, automation and advanced technology are no longer optional—they are essential. The best medium duty granulator manufacturers recognize this and incorporate the latest technological advancements to enhance machine efficiency, reduce manual intervention, and streamline operations.

Modern medium duty granulators often come equipped with programmable logic controllers (PLCs), automatic load sensing motors, and digital control panels. These advanced features enable precise control over the granulation process, ensuring optimal performance even under varying loads. Furthermore, features like automatic start-stop and self-adjusting feed systems enhance the granulator’s ability to operate autonomously, reducing the need for constant monitoring.

Energy efficiency is another key consideration in today’s environmentally conscious world. Manufacturers who focus on technology also prioritize energy-saving motors and eco-friendly designs that lower operational costs while improving the overall sustainability of the machine. Invoit Plast integrates the latest technological innovations into their medium duty granulators, ensuring that their machines not only meet the current needs of the plastic processing industry but also remain future-proof.

Providing Comprehensive After-Sales Support

Even the most well-designed granulator can encounter issues over time. That’s why after-sales support is a critical aspect to consider when selecting a granulator manufacturer. A great manufacturer doesn’t just sell a machine—they offer continuous support and service throughout the machine’s lifecycle.

Top manufacturers provide extensive maintenance packages, troubleshooting assistance, and rapid replacement of parts to minimize downtime. Regular maintenance schedules and training programs for operators ensure that the machines continue to run smoothly and at peak efficiency. Furthermore, having a reliable source for spare parts is essential, as delays in acquiring essential components can cause significant production losses.

In addition, Invoit Plast offers outstanding after-sales service and ensures the availability of spare parts and expert technical support. Their dedicated customer service team is always available to resolve issues and provide training, ensuring your medium duty granulator remains in top condition for years to come.

Innovation Through Research and Development

One of the hallmarks of the best medium duty granulator manufacturers is their investment in research and development (R&D). As the plastic processing industry evolves, so must the technology and designs used in granulators. Manufacturers who continuously innovate are able to provide state-of-the-art machinery that addresses new challenges and maximizes performance.

For instance, some manufacturers are now incorporating smart technology that allows operators to monitor and control the granulator remotely. Others are focused on making machines more energy-efficient, reducing noise levels, and improving the ease of cleaning and maintenance.

Invoit Plast is at the forefront of innovation, constantly enhancing their granulators through extensive R&D efforts. By investing in cutting-edge technology and staying ahead of industry trends, Invoit Plast ensures that their medium duty granulators remain some of the most efficient and reliable machines on the market.

Ensuring Compliance with National and International Standards

Manufacturers who prioritize compliance with industry standards demonstrate a commitment to delivering high-quality, safe, and reliable products. In India, many top-tier granulator manufacturers adhere to national standards such as those set by the Bureau of Indian Standards (BIS), as well as international standards like ISO and CE certifications.

These certifications not only ensure that the granulators are built to meet safety and quality requirements but also make them suitable for export to global markets. When purchasing a medium duty granulator, it’s important to check whether the manufacturer follows strict quality assurance protocols and complies with these established standards.

Invoit Plast is ISO-certified and adheres to both national and international standards, ensuring that their machines meet the highest quality, safety, and performance benchmarks.

In-House Manufacturing for Better Quality Control

A manufacturer with in-house manufacturing capabilities can better control the quality of its products, ensuring that each granulator meets the required specifications. Manufacturers who outsource major parts of their production are at risk of receiving inconsistent components that may not meet the same high-quality standards.

Invoit Plast prides itself on having complete control over the manufacturing process. From design to assembly, every aspect of the granulator’s production takes place within their facility. This allows for rigorous quality control at every step, resulting in machines that are more reliable and have better performance in the long run.

Focus on Ergonomics and Safety

When dealing with heavy-duty machinery, safety is a paramount concern. A reputable medium duty granulator manufacturer incorporates safety features that protect both the machine and the operators. Look for features like safety interlocks, emergency stop buttons, and overload protection that ensure safe and smooth operation.

In addition to safety, ergonomic design is also important. Machines should be easy to operate, clean, and maintain. Features like user-friendly control panels and easy-to-access maintenance points enhance the usability of the granulator and reduce the time spent on servicing.

Invoit Plast ensures that all their granulators meet strict safety standards and are designed for ease of use and maintenance. Their machines are equipped with essential safety features to protect operators and improve the overall working environment.

Why Choose Invoit Plast as Your Medium Duty Granulator Manufacturer

When selecting a medium duty granulator, it’s essential to work with a manufacturer who not only meets industry standards but also offers a combination of quality, innovation, and reliable support. Invoit Plast, based in Ahmedabad, India, is an industry leader in providing high-performance granulators designed for durability, efficiency, and cost-effectiveness.

With a focus on advanced technology, customization, excellent after-sales service, and rigorous quality control, Invoit Plast ensures that their medium duty granulators meet the diverse needs of industries such as plastic recycling, injection molding, and extrusion. Their commitment to continuous innovation and customer satisfaction makes them the ideal choice for businesses looking to optimize their plastic processing operations.

Partner with Invoit Plast for your medium duty granulator needs and experience the difference in performance, reliability, and customer service. Let Invoit Plast be your trusted partner in achieving sustainable, efficient, and cost-effective plastic processing solutions.