Gyro Screen

Gyro Screen

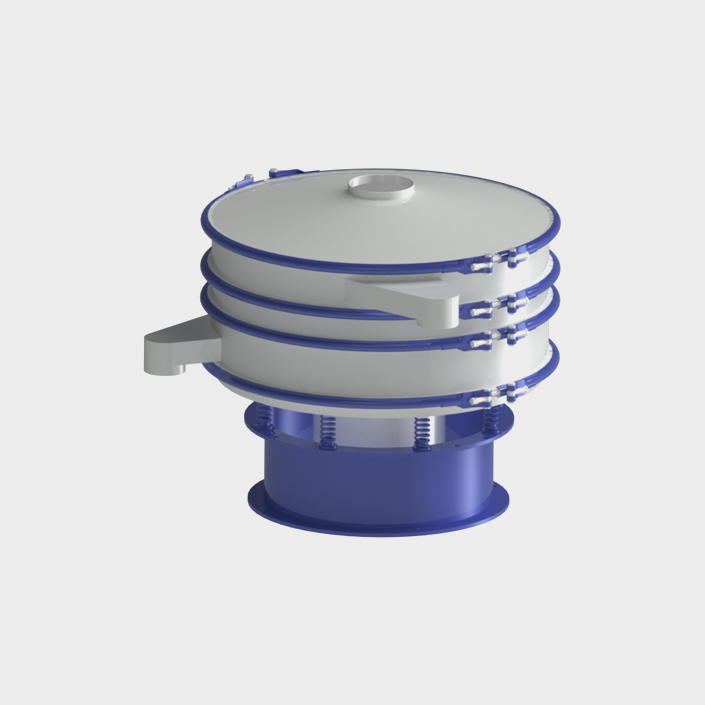

Invoit Plast Machinery Pvt Ltd is a leading manufacturer of high-performance Gyro Screens designed to address screening challenges such as sieving, grading, separating, and scalping bulk materials efficiently. Our Gyro Screens are easy to install in production lines and provide optimal screening capacity without requiring excessive floor space. These machines are engineered with precision to ensure complete material control and superior separation quality, making them the ideal solution for various industries.

Advanced Design & Functionality

The Gyro Screen operates on the principle of gyratory motion, which enhances the screening process and prevents blinding of sieves. The machine incorporates multi-directional vibrators, ensuring uniform material distribution and efficient separation. The discharge outlets can be easily repositioned, providing greater flexibility in placing collection bins or containers. This modular design makes our Gyro Screens highly adaptable and space-efficient compared to traditional screening equipment.

For industries requiring strict hygiene and durability, we offer Gyro Screens with fully stainless-steel bases, making them suitable for environments that demand frequent cleaning and maintenance. This is especially beneficial in the food and pharmaceutical industries, where a hygienic design is critical. For enhanced durability in corrosive environments, a fully stainless-steel unit with 316 stainless-steel contact parts is also available.

Applications

Our Gyro Screens are highly versatile and can be used across multiple industries, including:

- Plastic and Polymer Industry – Ensures accurate separation of plastic granules and powders.

- Minerals and Metals Industry – Efficiently screens ores, metal powders, and minerals.

- Pharmaceutical Industry – Provides high-precision screening for medicines and chemical compounds.

- Herbal and Chemical Industry – Ideal for filtering and grading herbal extracts and chemical powders.

- Ceramic Industry – Used for separating ceramic powders and slurry filtration.

- Dairy Industry – Helps in screening dairy powders and other milk-based products.

- Soap and Detergent Industry – Efficiently separates detergent powders and chemical formulations.

Key Features & Benefits

- Low Space Requirements: Compact and efficient design that saves valuable factory floor space.

- Lower Noise Levels: Designed with advanced technology to minimize operational noise.

- Dust-Proof Enclosed System: Prevents material contamination and ensures a clean working environment.

- Accurate Separation Efficiency: High-precision screening for maximum product quality.

- Greater Capacity: Handles a wide range of materials, including fine, wet, and difficult-to-screen substances.

- Minimum Blinding: Multi-directional vibrators reduce clogging and maximize productivity.

- Longer Screen Life: Durable construction ensures long-lasting performance and minimal maintenance.

- No Transmitted Vibration: Ensures stable operation without affecting surrounding equipment.

Why Choose Invoit Plast Machinery Pvt Ltd?

At Invoit Plast Machinery Pvt Ltd, we are committed to providing innovative and reliable screening solutions tailored to the specific needs of our clients. Our Gyro Screens are engineered for superior efficiency, durability, and adaptability, ensuring seamless integration into production processes across various industries. Whether you need a standard or customized solution, we have the expertise to deliver high-quality screening equipment that meets your requirements.