PVC Scrap Grinder Machine Manufacturer in Ahmedabad, India

Involt Plast Machinery Pvt. Ltd., located in Ahmedabad, India, is a leading manufacturer and supplier of advanced PVC and HDPE scrap grinders. With a strong reputation in the plastics recycling industry, we specialize in providing high-quality machines designed to meet the needs of various industries requiring efficient and reliable processing of scrap materials. PVC scrap grinders are essential tools for industries looking to reclaim and reuse materials, which not only help reduce environmental impact but also contribute to the efficient use of resources.

Supplying Industries for PVC Scrap Grinder

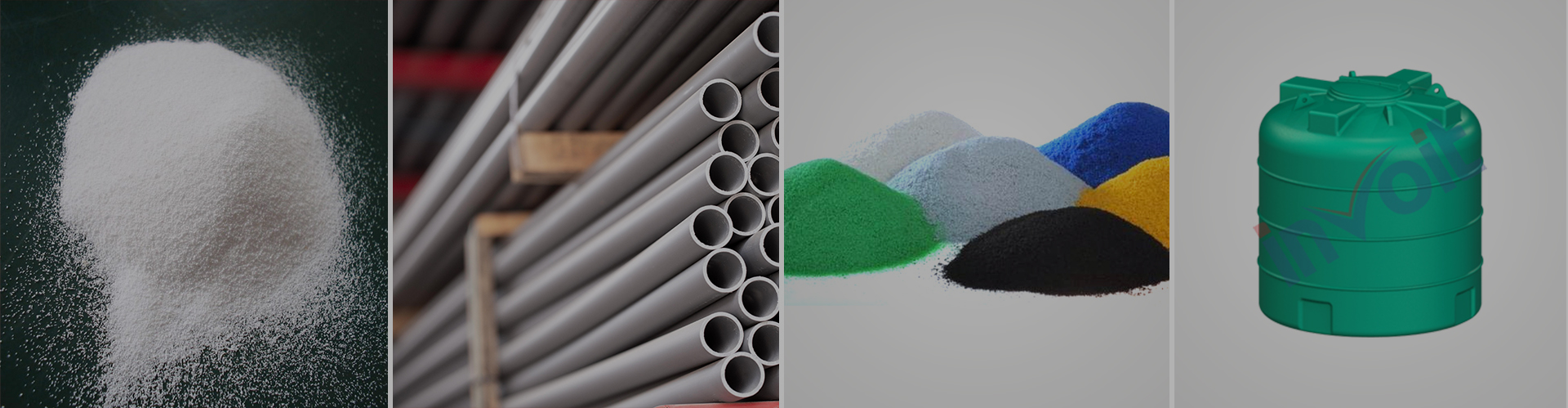

Our PVC scrap grinder is crucial in several industries where PVC is commonly used and waste material needs to be processed. The industries benefiting from PVC scrap grinders include:- Plastic Manufacturing: PVC is one of the most widely used plastics in manufacturing.

- PVC Pipes and Fittings: Companies involved in producing PVC pipes, fittings, and profiles can significantly benefit from the use of a PVC scrap grinder.

- Packaging Industry: In industries dealing with PVC packaging materials, recycling scrap helps in minimizing waste.

- Construction Industry: The use of PVC for window frames, doors, and other building materials leads to a large amount of scrap.

- Automotive Industry: PVC is used in a variety of automotive applications, from interior parts to exterior components.

- Furniture Industry: The demand for PVC in furniture production, especially for creating components such as chair legs, table frames, and upholstery, leads to waste that can be recycled with a PVC scrap grinder.

PVC Scrap Grinder Machine Manufacturer in Ahmedabad, India

Applications of PVC Scrap Grinder

PVC scrap grinder have a wide array of applications that help businesses in multiple sectors:

- Recycling PVC Waste: The primary function of PVC scrap grinders is to reduce scrap PVC into small, reusable particles

- Manufacturing of PVC Products: After the grinding process, the resulting granules or powder can be fed back into extrusion or molding machines to create new PVC products like pipes, profiles, flooring, and other components.

- Processing Defective Products: In manufacturing, defective or broken PVC products are a common by-product.

- Plastic Recycling Units: Independent recycling units that specialize in recycling PVC waste often rely on these grinders to process bulk PVC waste, which can then be resold to manufacturers for reuse.

- Injection Molding: Businesses that use injection molding technology to create PVC products also rely on PVC scrap grinders to recycle leftover or rejected products into reusable material, cutting down on the need for additional raw PVC.

- Construction Material Recycling: As mentioned, the construction industry generates significant amounts of PVC scrap, especially from doors, windows, and siding.

Why Choose Us for PVC Scrap Grinder ?

PVC scrap grinder, Involt Plast Machinery Pvt. Ltd. stands out as a trusted and innovative manufacturer in Ahmedabad, India. With years of experience and expertise in designing and manufacturing high-quality machinery, Involt Plast has garnered a reputation for delivering durable and efficient solutions for PVC recycling.- Customization: We provide tailored solutions to meet the unique requirements of your business. Whether you need a grinder for large-scale industrial use or for smaller operations, our machines can be customized for optimum performance.

- Durability and Efficiency: Our PVC scrap grinders are built with high-quality materials to ensure long-lasting durability. We use advanced technology to make sure the grinders operate with maximum efficiency and minimal energy consumption.

- Advanced Features: Our grinders are equipped with the latest features, such as precision cutting, high-speed operation, and low maintenance, ensuring that they can handle large volumes of PVC scrap with ease.

- Cost-Effective: By choosing our PVC scrap grinders, you invest in machinery that helps reduce waste and save on material costs

- Environmentally Friendly: Recycling PVC waste using our grinders promotes a sustainable business model.

- Comprehensive After-Sales Support: We believe in building long-term relationships with our clients

- Proven Track Record: With a proven track record of successful installations and satisfied customers across various industries, Involt Plast has earned a reputation as a leader in PVC scrap grinder manufacturing in Ahmedabad, India.

- Timely Delivery: Commitment to delivering machines on schedule to keep your operations running smoothly.

Our Expertise

At Involt Plast, we don’t just manufacture PVC scrap grinders; we excel at providing solutions that enhance your business’s productivity and sustainability. Here’s a breakdown of our expertise:

- Design and Engineering Excellence: We have a team of engineers who focus on designing grinders with the latest technological advancements, ensuring efficient performance and longevity.

- Tailored Solutions: We understand that each business has unique needs. Our team works closely with clients to customize PVC scrap grinders that best suit their production requirements.

- Advanced Manufacturing Facilities: Our state-of-the-art manufacturing facilities allow us to produce high-quality grinders with precision, ensuring they meet the highest standards.

- Quality Assurance: Every grinder undergoes rigorous quality checks to ensure reliability and performance.

- Research and Development: We invest in continuous R&D to innovate and improve our products. By staying ahead of industry trends, we ensure our grinders are at the forefront of technology.

- Customer-Centric Approach: We prioritize customer satisfaction. From consultation to installation and beyond, we provide exceptional support to ensure our clients’ needs are met.

| Model No | Feeding Hopper A x B (mm) | Blade | Mesh Hole | Motor | Output (kg/hr) |

Machine Dimension L x W x H (mm) |

Weight (Kg) |

|

| Fix | Rotary | (mm) | KW / HP | |||||

| GRA0800001 | 210 X 185 | 2 | 6 | 8 | 2.2 / 3 | Upto 45 | 700 X 450 X 1000 | 130 |

| GRA1200001 | 310 X 210 | 2 | 9 | 8 | 3.7 / 5 | Upto 60 | 1000 X 750 X 1300 | 300 |

| GRA1600001 | 410 X 365 | 2 | 12 | 10 | 7.5 / 10 | Upto 125 | 1250 X 800 X 1650 | 470 |

| GRA1800001 | 450 X 365 | 2 | 9 | 12 | 11.5 / 15 | Upto 150 | 1250 X 850 X 1650 | 515 |

| GRA2000001 | 510 X 365 | 4 | 15 | 12 | 11.5 / 15 | Upto 180 | 1250 X 900 X 1650 | 535 |

| GRA2400001 | 610 X 570 | 4 | 6 | 16 | 22.5 / 30 | Upto 300 | 2100 X 1300 X 2000 | 1280 |

| GRA2800001 | 715 X 570 | 4 | 6 | 18 | 22.5 / 30 | Upto 350 | 2250 X 1500 X 2200 | 1500 |

| GRA3200001 | 815 X 715 | 4 | 6 | 20 | 30 / 40 | Upto 500 | 2300 X 1500 X 2300 | 1900 |

| GRA3600001 | 915 X 715 | 4 | 6 | 25 | 37 / 50 | Upto 600 | 2400 X 1650 X 2300 | 2000 |

| GRA4000001 | 1020 X 715 | 4 | 6 | 25 | 37 / 50 | Upto 700 | 2400 X 1650 X 2300 | 2200 |

Machinery Notes Of PVC Scrap Grinder Machine:

- Max. Capacity of the machine is subject to diameter of screen mesh and composition & Properties of the material.

- Noise level varies with different materials and motor types.

- To avoid plastic from sticking to the blades. All materials should be crushed at normal temperature.

- Power Supply : 3ø, 230 / 400 / 460 / 575VAC, 50 / 60Hz.

- We reserve the right to change specifications without prior notice.