Industrial material handling has always been an essential part of manufacturing processes. The effective movement of bulk materials within factories, warehouses, and plants is critical to the efficiency of the operation. Among the most versatile and widely used equipment in industrial material handling are screw conveyors. These machines play a significant role in ensuring that materials are transported efficiently, safely, and in an organized manner. As industries demand greater productivity, screw conveyors have become an integral part of the landscape of material handling.

In this blog, we will explore the pivotal role screw conveyors play in industrial material handling, their applications, and the factors to consider when selecting the right conveyor system. We will also look at the design considerations and provide some helpful tips for businesses looking to improve their material handling processes. Additionally, we’ll take a closer look at Invoit Plast, a leading manufacturer in India, known for its superior screw conveyor solutions.

Understanding Screw Conveyors

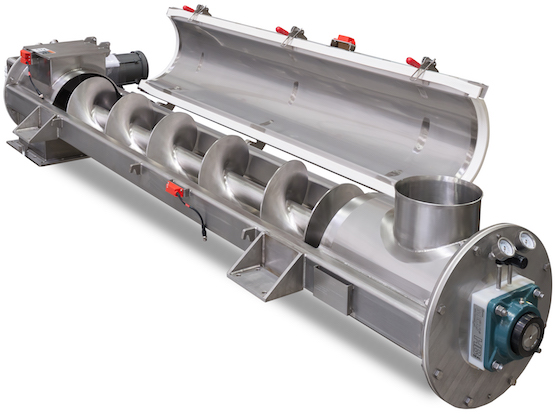

Screw conveyors are mechanical devices used to transport bulk materials through a rotating helical screw. These conveyors are powered by an electric motor, which drives the screw to move materials along a trough or tube. The screw’s helical design pushes the material forward, making it one of the most efficient ways to transfer solids, powders, or granules within an industrial setting.

Screw conveyors are especially beneficial in applications where other forms of material handling—such as belt conveyors or pneumatic conveyors—are impractical. These machines offer several advantages, including versatility, ease of maintenance, and cost-effectiveness. Whether moving dry bulk solids like grain, sand, or cement, or even more specialized materials, screw conveyors can be tailored to suit almost any industrial need.

Why Screw Conveyors Are Essential for Industrial Material Handling

Screw conveyors play a vital role in industrial material handling systems, providing a reliable, efficient means of transporting materials across various sectors. They are designed to work in harsh environments, handling materials in demanding settings such as manufacturing plants, power plants, chemical factories, and food processing plants. Here’s why they are so essential:

- Efficient Material Transport: Screw conveyors can easily move bulk materials over short to medium distances, whether horizontally, vertically, or at an incline. This versatility makes them ideal for industries requiring reliable material transport in multiple directions.

- Compact and Space-Saving: Unlike other conveyors that require expansive space for operation, screw conveyors are compact and can be installed in tight spaces. Their ability to move materials in a straight line or at any angle helps in conserving valuable floor space in crowded manufacturing environments.

- Gentle Handling: In certain industries, materials need to be transported without damaging their integrity. Screw conveyors provide gentle handling for bulk materials, preventing breakage or degradation, which is crucial for materials like food products or fragile chemicals.

- Closed System: Screw conveyors are particularly useful in environments where it is essential to prevent spillage, dust emission, or contamination. Their enclosed design ensures that the materials are safely contained, reducing waste and maintaining cleanliness.

- Ease of Customization: Screw conveyors are highly customizable in terms of design, material selection, and features. For example, the screw design, speed, and capacity can be adjusted to meet the specific requirements of the bulk material being transported. This flexibility allows screw conveyors to be used across a wide range of industries.

Common Screw Conveyor Applications

Screw conveyors are found in numerous industries, playing an essential role in material handling and contributing to various applications. Some of the most common screw conveyor applications include:

- Bulk Material Handling: Industries that deal with bulk solids, such as grain processing, cement manufacturing, and chemical production, heavily rely on screw conveyors to move large quantities of materials.

- Food Processing: In the food industry, screw conveyors are used to move grains, powders, spices, and other dry food ingredients without contamination. Their gentle conveying system ensures that food items remain intact during transport.

- Waste Treatment and Recycling: Screw conveyors are commonly used in waste treatment facilities, helping move and sort materials for recycling or disposal. Their ability to handle wet, sticky, and difficult materials makes them invaluable in this field.

- Mining and Quarrying: For industries involved in mining and quarrying, screw conveyors are employed to handle ores, coal, and other minerals. The heavy-duty nature of screw conveyors makes them ideal for this rugged environment.

- Pharmaceutical Manufacturing: In the pharmaceutical sector, screw conveyors are used to transfer powdered or granulated chemicals safely. The closed-system design ensures that no materials are lost, preserving the integrity of the ingredients.

- Construction: Screw conveyors play a key role in construction, moving materials like cement, sand, and aggregates from one place to another. Their adaptability to different types of bulk materials makes them indispensable in this industry.

Screw Conveyor Design and Considerations

When designing a screw conveyor, there are several factors to consider to ensure the system is efficient and meets the specific needs of the material handling process. These design considerations include:

- Material Type: The characteristics of the material being handled determine the screw conveyor’s design. For example, a fine powder might require a different screw design than larger, bulkier items. Material properties such as moisture content, abrasiveness, and flow characteristics are essential when determining the correct screw conveyor system.

- Conveyor Length and Inclination: The distance over which the material needs to be transported plays a significant role in the design of the conveyor system. Screw conveyors can be designed to operate horizontally, inclined, or vertically. The incline of the conveyor affects the material flow rate and the design of the screw.

- Capacity: The volume of material to be conveyed is another important consideration. The conveyor’s diameter, screw pitch, and speed must be optimized to handle the desired throughput. Overloading the system can lead to inefficiency, excessive wear, and even failure.

- Material Flow Characteristics: The flowability of the material is another crucial consideration when designing a screw conveyor. If the material tends to pack or form clumps, adjustments must be made to ensure smooth operation. The helix angle of the screw and the arrangement of the conveyor should be optimized to handle materials with poor flow properties.

- Wear Resistance: Depending on the materials being transported, screw conveyors may experience significant wear and tear over time. It’s important to choose the right materials for the construction of the screw, flight, and housing to ensure durability and reduce maintenance costs.

- Power Requirements: The power needed to operate a screw conveyor depends on the type of material, its flow characteristics, and the length of the conveyor. Correctly calculating the required power will ensure the system operates efficiently and prevents underperformance or overuse of energy.

Tips for Optimizing Your Screw Conveyor System

If you’re in the business of material handling, optimizing your screw conveyor system can lead to significant improvements in productivity and efficiency. Here are some tips to help you get the most out of your screw conveyors:

- Regular Maintenance: Periodic maintenance of screw conveyors can significantly extend their lifespan. Routine checks for wear and tear, as well as lubrication of moving parts, are crucial to keeping the system running smoothly.

- Proper Sizing: One of the most common mistakes is underestimating or overestimating the size of the screw conveyor. An appropriately sized conveyor will help avoid bottlenecks and ensure optimal material flow.

- Use the Right Materials: Choose materials that are well-suited to the type of material being conveyed. For instance, stainless steel is a good choice for corrosive materials, while carbon steel might be more appropriate for dry, non-corrosive substances.

- Monitor System Performance: Continuously monitoring the system’s performance allows you to identify potential issues early on. Keep an eye on the conveyor’s speed, temperature, and power consumption to ensure everything is functioning efficiently.

- Work with Experienced Suppliers: Collaborating with a reliable screw conveyor supplier can help you design a system that meets your specific needs. Experienced suppliers understand the nuances of industrial material handling and can guide you in selecting the best equipment.

Invoit Plast: Leading Screw Conveyor Manufacturer in India

Invoit Plast is a leading manufacturer of screw conveyors in India, specializing in providing top-quality conveyor systems for a wide range of industrial applications. With years of experience and a commitment to excellence, Invoit Plast offers innovative solutions tailored to the unique needs of each industry.

Their products are known for durability, efficiency, and reliability. As a leading screw conveyor manufacturer, Invoit Plast offers customized designs to meet the specific requirements of different industries, including bulk material handling, food processing, and chemical production.

By working with Invoit Plast, businesses can gain access to cutting-edge conveyor technology, ensuring seamless material handling and improved productivity. Whether you’re looking for a simple screw conveyor or a more complex system, Invoit Plast has the expertise to help you achieve optimal results.

Screw conveyors are integral to modern industrial material handling, providing a reliable, efficient, and cost-effective solution for transporting bulk materials. With the ability to customize designs to suit various industries, screw conveyors are adaptable to a wide range of applications, from mining and construction to food processing and pharmaceuticals. By optimizing your screw conveyor system and choosing the right manufacturer, you can improve your material handling process, reduce downtime, and increase overall productivity. If you’re looking for high-quality screw conveyors, Invoit Plast stands out as a leading manufacturer in India, offering tailored solutions for diverse industries.